![]()

Profession - Senior

Mechanical Engineer - Mark Case, P.E.

Design anything that moves... Take advantage of best (maybe the latest) technology. Listen

to the people that know... the operator and the maintenance person.

Experience & Education

| Project Engineer - Genie Industries, a division of Terex (Aerial Work

Platforms) Designed hydraulic and electric drive systems, computer controlled electro-hydraulic systems and vehicle wiring systems. | |

| Design and Project Engineer - Goldendale Aluminum 12 years. Focus in project management, machine design (including numerous electro-hydraulic, PLC controlled machines.) Performed troubleshooting on large, complex machinery. | |

| Designer/Liaison Engineer Freightliner Corporation Performed cab structural design for military truck vehicle project(2,600 units). Followed truck through production line made modifications to design while in manufacture, communicated design changes necessary for manufacturing process capability to designers for all aspects of vehicle. Corrected design of cab and related components. | |

| Bachelor of Science in Mechanical Engineering (BSME) - Washington State University, 1988 | |

| Registered Professional Engineer (P.E.) - State of

Washington | |

| Private Pilots license |

Mechanical Design Have designed numerous machines and systems ranging from material handling to piping systems, to emissions control systems, hydraulic presses, and numerous other purpose built machines for performing various tasks in the hot, dirty, rough and tumble world of an aluminum smelter.

Solid Modeling AutoCAD Mechanical Desktop, Autodesk Inventor and Solidworks. I have used CAD in all phases of mechanical and electrical design for 15 years. Have been using solid modeling for ten years. Currently 90% of all of my new designs are solid models.

PLC Programming Have applied PLCs of numerous types of mobile equipment (a very demanding environment for PLCs). Proficient in Allen Bradley SLC 500 and PLC 5(with RsLogix). Applied OPTO22 hardware for control of environmental systems- utilized cascaded PID loops. Mobile PLCs were Automation Direct(Koyo/PLCDirect) with PID loops and wireless Ethernet connection for remote control of stationary equipment and for display of information from central company database to vehicle mounted touchscreen.

Hydraulic Design Designed and specified numerous industrial and mobile hydraulic systems. Well versed in proportional hydraulic valve technology and integration with electric remote proportional joysticks and PLC controllers.

Educator Developed a curriculum for and taught beginning through advanced courses in Computer Aided Design with AutoCAD at Yakima Valley Community College and Columbia Gorge Community College.

Ventilation Design

Support of Employee Involvement

Project Management

Click to Enlarge  Click here

for more details

Click here

for more details

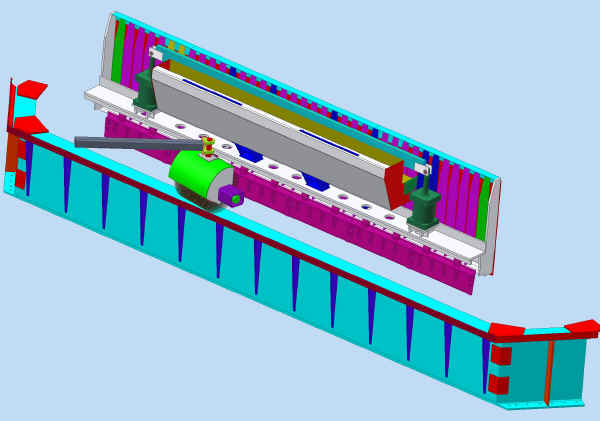

- Feed Screw is controlled by a PLC monitoring an encoder built into the hydraulic drive motor to achieve precise doses. The spreader attachment forms a dam of dispensed material, against which, the screw pushes- - this results in a dustless operation.

Ore Deck Trimmer

|

|